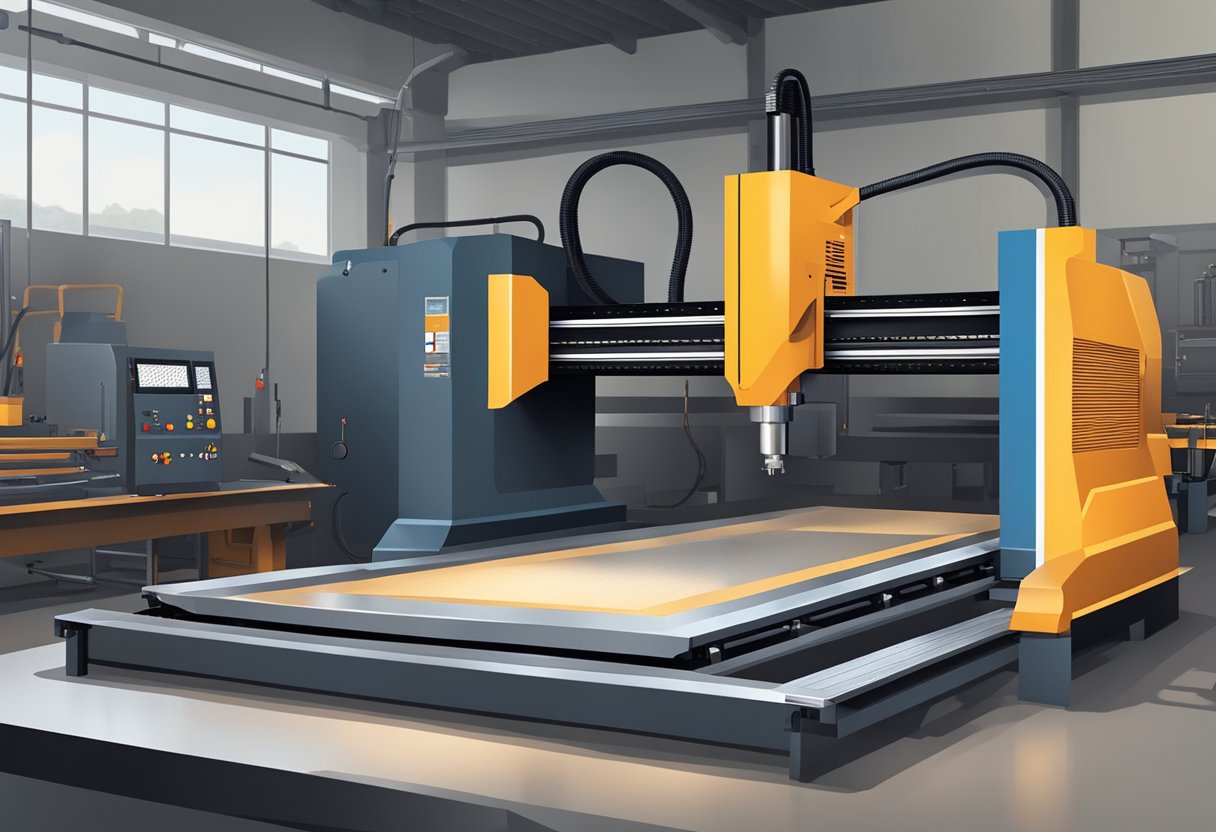

CNC plasma cutting is a high-tech method for slicing through metal with amazing speed and accuracy. It uses a plasma taskulamppu guided by a computer to create precise cuts in various materials. This cutting-edge technology offers major benefits over old-school cutting methods, including faster speeds, cleaner edges, and the ability to cut complex shapes.

The process works by sending an electric arc through a gas to create plasma – a super-hot ionized gas. This plasma stream then melts through the metal workpiece. A CNC (computer numerical control) system directs the torch’s movement, allowing for intricate designs and repeatability.

For shops and factories, CNC plasma cutting opens up new possibilities. It can handle thick metals that other methods struggle with. The computer control also means less waste and fewer mistakes. Whether you need to cut parts for machines, signs, or art projects, CNC plasma cutting delivers great results.

Key Takeaways

- CNC plasma cutting uses computer-guided plasma to slice metal quickly and precisely

- It offers faster speeds and cleaner cuts compared to traditional methods

- The technology can handle thick materials and create complex shapes with accuracy

Getting Started: Essential Equipment And Setup

Setting up a CNC plasma cutting system requires careful planning and the right tools. Let’s explore the key components and steps needed to get your plasma cutting operation up and running.

Core Equipment Requirements

A CNC plasma cutting setup needs several essential pieces of equipment:

- CNC table or gantry system

- Plasma cutter

- Computer with CAD/CAM software

- Air compressor

- Ventilation system

- Safety gear (welding helmet, gloves, fire-resistant clothing)

The CNC table provides the framework for accurate cuts. A good air compressor is crucial for clean cuts. Proper ventilation keeps the work area safe from fumes.

Selecting The Right CNC Plasma Cutter

Choosing a plasma cutter depends on your needs:

- Cut thickness: Match the cutter to the metal thickness you’ll work with most

- Duty cycle: Higher duty cycles allow longer continuous cutting

- Cut quality: Better cutters produce smoother edges

- Power requirements: Make sure your shop can handle the cutter’s power needs

For beginners, a 40-50 amp cutter is often a good start. More advanced users might opt for 80-100 amp models for thicker materials.

Necessary Software And Design Tools

Software is key to CNC plasma cutting:

- CAD (Computer-Aided Design) software for creating designs

- CAM (Computer-Aided Manufacturing) software to convert designs into machine code

- CNC control software to operate the cutting machine

Popular CAD options include Fusion 360 and LibreCAD. For CAM, try SheetCAM or PyCAM. Many CNC machines use GRBL as control software.

Basic design tools like rulers, squares, and calipers are also helpful for measuring and planning cuts.

Basic Setup Procedures

Setting up your CNC plasma cutter involves these steps:

- Assemble the CNC table according to manufacturer instructions

- Mount the plasma torch to the gantry

- Connect the plasma cutter to the CNC controller

- Install and configure the control software on your computer

- Level the cutting surface

- Test the system with simple cuts

- Calibrate the torch height control

Take time to learn your machine’s safety features. Always keep a fire extinguisher nearby. Regular maintenance, like cleaning and lubricating moving parts, will keep your setup running smoothly.

Technical Fundamentals: Understanding Cutting Parameters

CNC plasma cutting relies on several key parameters that directly impact cut quality and efficiency. Proper adjustment of these factors is crucial for achieving optimal results across different materials and thicknesses.

Critical Parameters Affecting Cut Quality

Cut quality in plasma cutting depends on several vital factors. Amperage controls the power of the plasma arc, affecting cut speed and thickness capacity. Higher amperage allows faster cutting of thicker materials. Gas pressure and flow rate influence arc stability and cut edge quality. Proper gas settings prevent dross formation and ensure clean cuts.

Torch standoff distance impacts cut width and angle. Closer distances produce narrower kerfs but risk damaging the torch. Longer standoffs may cause wider, less precise cuts. Nozzle size selection is based on material thickness and desired cut quality. Smaller nozzles offer finer cuts but limit speed and thickness capacity.

• Amperage: Higher for thicker materials • Gas settings: Pressure and flow rate • Torch standoff: Affects kerf width

• Nozzle size: Matches material thickness

Pierce Height And Cut Height Optimization

Pierce height refers to the torch distance when starting a cut. It’s typically set higher than cut height to prevent molten metal splatter. Proper pierce height allows for clean hole initiation without damaging the torch.

Cut height is the torch-to-workpiece distance during cutting. It affects cut quality, kerf width, and kuluttavaa elämää. Too low can cause double arcing and nozzle damage. Too high reduces cut quality and speed. Most systems use automatic height control to maintain optimal distance.

Ideal heights vary by material:

- Thin sheet: 1.5mm pierce, 1mm cut

- Thick plate: 8mm pierce, 4mm cut

Test cuts help fine-tune heights for best results.

Cut Speed Considerations

Cut speed directly impacts productivity and quality. Faster speeds boost output but may reduce cut quality. Slower speeds can improve quality but lower efficiency. The ideal speed balances these factors.

Material type and thickness are key speed determinants. Thinner materials allow faster cutting. Tougher alloys require slower speeds. Power source capacity also limits maximum speed.

Cut speed affects: • Kerf width • Dross formation • Edge squareness • Surface finish

Start with recommended speeds from cutting charts. Adjust based on observed cut quality. Gradual increases often yield the best balance of speed and quality.

Material-Specific Adjustment Techniques

Different materials require unique parameter adjustments for optimal cutting. Mild steel is forgiving and works well with oxygen as the plasma gas. Stainless steel benefits from nitrogen or N2/H2 mixes to prevent oxidation. Aluminum often uses air or nitrogen with higher amperage.

For mild steel: • Use oxygen as plasma gas • Set higher amperage for thick plates • Adjust speed based on thickness

Stainless steel tips: • Use N2 or N2/H2 mix gas • Lower amperage than mild steel • Slower speeds for clean edges

Aluminum cutting: • Air or N2 plasma gas • 10-20% higher amperage • Faster speeds than steel

Test cuts on scrap material help dial in settings. Regular parameter tweaks ensure consistent quality across varying stock.

Precision Techniques For Superior Cutting Quality

Achieving top-notch results in CNC plasma cutting requires careful attention to detail and mastery of key techniques. By focusing on proper setup and execution, operators can significantly boost cut quality and consistency.

Torch Positioning Strategies

Correct torch height and angle are crucial for clean cuts. Keep the torch perpendicular to the workpiece, typically 1/16 to 1/8 inch above the surface. Use arc voltage height control to maintain consistent standoff as the material warps from heat. Tilt the torch 3-5 degrees in the direction of travel for straighter cuts on thicker materials.

For piercing, start with the torch slightly higher and slowly lower it as the arc develops. This prevents molten metal from splashing back and damaging the consumables. On corners, slow down and lift the torch slightly to prevent overheating and rounded edges.

Consumables Selection And Maintenance

Picking the right consumables makes a big difference in cut quality. Match the nozzle and electrode to your specific material and thickness. Use copper nozzles for most jobs, but switch to chrome-plated ones for oxygen cutting of steel.

Check consumables regularly for wear. Replace the nozzle when the orifice becomes oval or enlarged. Swap out electrodes once the pit depth reaches 1/16 inch. Clean consumables after each use to remove spatter and debris. This extends their life and keeps cuts crisp.

Proper gas flow is essential. Set oxygen pressure according to the chart for your torch model. For non-ferrous metals, use nitrogen or air instead.

Speed And Material Thickness Correlations

Cutting speed varies based on material type and thickness. Start with the manufacturer’s recommended speeds, then fine-tune:

| Materiaalin paksuus | Mild Steel (IPM) | Stainless Steel (IPM) | Aluminum (IPM) |

|---|---|---|---|

| 1/4 inch | 80-100 | 60-80 | 100-120 |

| 1/2 inch | 45-65 | 35-55 | 60-80 |

| 1 inch | 20-30 | 15-25 | 30-40 |

Slower speeds produce cleaner cuts but risk excess heat input. Faster speeds may leave dross. Find the sweet spot for each job.

Best Practices For Consistent Results

Proper machine setup is key. Level the cutting table and check for squareness. Clean the slats regularly to prevent warping of thin materials. Use a square to verify the torch is perpendicular to the workpiece.

Preheat thicker materials to reduce thermal stress and improve cut quality. For steel over 1 inch thick, preheat to 200-300°F.

Cut from the outside edge inward on holes to minimize distortion. When cutting multiple parts, start with interior features before cutting the outer profile.

Keep the work area clean and dry. Moisture can affect cut quality and consumable life. Regular calibration of the height control system ensures consistent performance.

Safety And Operational Guidelines

CNC plasma cutting requires careful attention to safety protocols and best practices. Proper equipment, workspace setup, and handling procedures are essential to protect operators and maintain efficient operations.

Henkilökohtaiset suojavarusteet (PPE)

Plasma cutting produces intense light, heat, and fumes. Operators must wear:

- Welding helmet with proper shade rating

- Fire-resistant clothing covering all skin

- Leather gloves and steel-toed boots

- Respirator to filter fumes and particles

Eye and skin protection are crucial. Regular safety glasses aren’t enough – a full-face shield is needed. Earplugs help reduce noise exposure during long cutting sessions.

Workspace Preparation

A clean, organized workspace promotes safety. Key steps include:

- Clear the area of flammable materials

- Use fire-resistant curtains or screens

- Ensure proper ventilation to remove fumes

- Keep a fire extinguisher nearby

- Mark off a “no-go zone” around the cutting area

Good lighting helps operators see clearly. Anti-fatigue mats reduce strain during long shifts. A first aid kit should be easily accessible in case of minor injuries.

Risk Mitigation Strategies

Identify and address potential hazards before starting work:

- Inspect all equipment and connections

- Train operators on emergency procedures

- Use proper grounding to prevent electric shock

- Store compressed gas cylinders securely

- Keep work area dry to avoid slip hazards

Regular maintenance checks help catch issues early. Creating a safety checklist ensures nothing is overlooked. Encourage a culture where workers feel comfortable reporting safety concerns.

Handling And Operational Safety Protocols

Safe machine operation requires careful attention:

- Never leave the machine unattended while cutting

- Keep hands and tools away from the cutting area

- Use proper material handling techniques for heavy pieces

- Follow manufacturer guidelines for machine settings

- Allow cut pieces to cool before handling

Proper material storage prevents tripping hazards. Clean the work area after each use. Regularly check and replace consumable parts like elektrodit ja suutins to maintain cut quality and safety.

Troubleshooting And Avoiding Common Mistakes

CNC plasma cutting can be tricky, but knowing how to spot and fix issues is key. Let’s look at ways to troubleshoot problems and keep your cuts clean.

Identifying Potential Cutting Errors

Common cutting errors include rough edges, dross buildup, and incomplete cuts. Look for signs like:

- Uneven cut lines

- Excessive sparking

- Slow cutting speed

- Warped edges

These can point to issues with machine settings or consumables. Check your speed, amperage, and torch height first. If those look good, inspect your consumables for wear.

A table can help track errors:

| Error | Possible Cause | Fix |

|---|---|---|

| Karkeat reunat | Too high speed | Lower cutting speed |

| Kuonan kerääntyminen | Low amperage | Increase amperage |

| Incomplete cuts | Worn consumables | Replace nozzle/electrode |

Diagnostic Approaches

When issues pop up, take a step-by-step approach:

- Check machine settings

- Inspect consumables

- Test on scrap material

- Adjust one factor at a time

Keep a log of changes and results. This helps track what works and what doesn’t. Don’t be afraid to make small tweaks – sometimes a tiny adjustment can make a big difference.

Try different cut directions or lead-in methods if you’re still having trouble. Sometimes, the way you approach the cut matters as much as the settings.

Preventive Maintenance Techniques

Regular upkeep keeps your machine cutting smooth. Here’s a simple checklist:

- Clean the torch daily

- Check gas and water lines weekly

- Inspect cables for wear monthly

- Lubricate moving parts as needed

Don’t skip these steps! A well-maintained machine cuts better and lasts longer. It’s worth the time investment.

Keep spare parts on hand, especially consumables. This way, you’re not stuck waiting for replacements when something wears out.

Konteasian hallinta

Consumables are the workhorses of your plasma cutter. Treat them right:

- Store in a dry place

- Handle with care to avoid damage

- Replace at the first sign of wear

Tip: Mark your consumables with the date you started using them. This helps track their lifespan.

A good rule of thumb: change nozzles and electrodes as a set. They wear together, so replacing one without the other can lead to poor cuts.

Keep an eye on your gas flow and quality too. Bad gas can wreck even new consumables fast.

Industry Applications And Versatility

CNC plasma cutting has become a go-to technology across many industries. Its ability to cut various metals with precision and speed makes it a valuable tool for many businesses.

Automotive Sector Uses

Car makers use CNC plasma cutting to create body panels, chassis parts, and custom components. The tech helps cut steel, aluminum, and other metals for vehicle frames and structures. It’s great for making prototypes fast. Shops can quickly produce one-off parts for classic car restorations too.

Some key benefits in auto work:

- Fast cutting of thick metals

- Ability to make complex shapes

- Less material waste than other methods

- Good for both mass production and custom jobs

Construction And Manufacturing Applications

Building and factory work rely on CNC plasma cutting a lot. It’s used to cut beams, pipes, and sheets for big projects. The machines can make holes for bolts and create perfect edges for welding.

Common uses include:

- Cutting steel frames for buildings

- Making HVAC ductwork

- Fabricating metal signs and artwork

- Cutting parts for heavy machinery

Many shops use it to make metal stairs, railings, and decorative items too. The tech is flexible enough for both large-scale jobs and smaller custom work.

Emerging Industrial Trends

New uses for CNC plasma cutting are popping up all the time. 3D plasma cutting is getting more popular. It lets machines cut at angles and make complex 3D shapes. This opens up new design options.

Some cool new trends:

- Underwater plasma cutting for shipyards

- Robotic arms with plasma torches for tricky cuts

- High-def plasma for super precise work

- Combo machines that can plasma cut and mill

Green tech is big too. New systems use less power and create less waste. This makes the process more eco-friendly and cost-effective.

Potential For Custom Fabrication

CNC plasma cutting shines in custom work. It’s great for artists, small shops, and DIY fans. The machines can cut intricate designs in metal. This is perfect for making signs, sculptures, and decorative items.

Examples of custom work:

- Metal art and wall hangings

- Custom car parts

- Personalized metal gifts

- One-off machine parts

Small businesses love the tech. It lets them offer unique products without huge costs. Home users can even buy smaller CNC plasma cutters for personal projects now.

Future Of CNC Plasma Cutting Technology

CNC plasma cutting is set to evolve rapidly in the coming years. New advancements will make the process faster, more precise, and easier to use for businesses of all sizes.

Markkinoiden kasvuennusteet

The CNC plasma cutting market is expected to grow significantly by 2030. Experts predict a compound annual growth rate of 5-7% over the next 5 years. Key factors driving this growth include:

• Rising demand in automotive and aerospace industries • Increased use in construction and shipbuilding • Growing adoption by small and medium businesses

As prices come down, more companies will be able to afford CNC plasma cutting systems. This will expand the customer base beyond large manufacturers.

Technological Innovations

Several exciting innovations are on the horizon for CNC plasma cutting:

• Higher power plasma torches (400+ amps) for cutting thicker materials • Improved nozzle designs for finer, more precise cuts • Advanced gas mixing systems for better cut quality • Smarter height control for consistent cutting on uneven surfaces

New sensors and AI will allow machines to automatically adjust settings for optimal cuts. This will reduce the skill needed to operate the equipment.

Automation And Software Integration Trends

Automation is set to transform CNC plasma cutting operations:

• Robotic loading/unloading systems • Automated part sorting and stacking • Integration with warehouse management software

Cloud-based design libraries will let users quickly access and modify part files. Improved nesting software will maximize material usage and cut time.

Real-time monitoring will allow remote troubleshooting and predictive maintenance. This will minimize downtime and extend machine life.

Potential Industry Transformations

CNC plasma cutting may reshape several industries:

• On-demand manufacturing of custom metal parts • Decentralized production closer to end customers • New metal recycling and upcycling business models

3D plasma cutting could enable complex curved cuts for aerospace parts. Micro-plasma cutting may find uses in electronics manufacturing.

As the technology improves, CNC plasma cutting will likely replace some traditional metal fabrication methods. This could lead to major shifts in manufacturing processes across multiple sectors.

Johtopäätös

CNC plasma cutting is a powerful technology for precise metal fabrication. Proper setup and technique are key to getting clean, accurate cuts. Using the right consumables, adjusting settings for each material, and maintaining the machine help ensure good results.

Safety should always come first. Protective gear like welding helmets and gloves are essential. Good ventilation removes fumes and dust. Keeping the work area clear prevents accidents.

With practice, operators can master controlling cut speed and height. This allows for intricate designs and smooth edges. Regular cleaning and part replacement keep the system running smoothly.

CNC plasma cutters open up many possibilities for custom metal projects. From signs to machine parts, they offer flexibility and efficiency. As the technology advances, even more applications are emerging.

Investing time in learning best practices pays off. It leads to higher quality cuts, less wasted material, and faster production. For shops large and small, CNC plasma cutting is a valuable tool.