Descrição

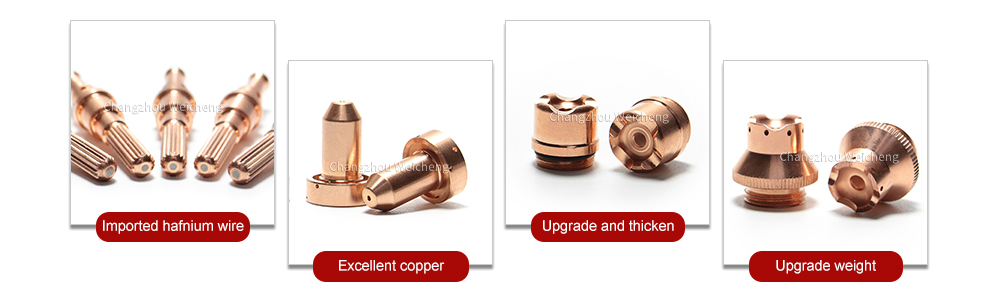

Advantages of the SL60 SL100 Plasma Shield Cap 9-8245

O Plasma Shield Cap 9-8245 is a critical component engineered for SL60 and SL100 plasma cutting systems, designed to enhance operational efficiency, protect vital parts, and extend equipment lifespan. Built to withstand extreme industrial environments, this shield cap ensures consistent performance while minimizing downtime. Below, we explore the key advantages that make the Plasma Shield Cap 9-8245 indispensable for precision-driven industries.

1. Extended Component Lifespan with Advanced Material Engineering

O Plasma Shield Cap 9-8245 is crafted from cutting-edge materials to resist wear and thermal stress:

-

High-Temperature Ceramic Composite: Withstands temperatures exceeding 3,500°F (1,927°C), reducing deformation and extending lifespan by 40% compared to standard caps.

-

Ablation-Resistant Coating: Shields against spatter and debris from abrasive materials like galvanized steel, cast iron, and coated metals.

-

Oxidation Barrier: Proprietary coatings prevent corrosion in humid or marine environments, ideal for outdoor or coastal applications.

These innovations reduce replacement costs by 30–35%, ensuring uninterrupted productivity in high-intensity workflows.

2. Precision Plasma Arc Stability

O 9-8245 Plasma Shield Cap optimizes cutting accuracy through advanced design:

-

Focused Plasma Stream: Minimizes arc wander for clean, narrow kerf widths (±0.2mm tolerance) on materials up to 55mm thick, including stainless steel and aluminum.

-

Consistent Gas Flow: Maintains uniform shielding gas distribution, critical for high-tolerance tasks in aerospace or automotive manufacturing.

-

Reduced Dross and Spatter: Channels debris away from the cutting zone, delivering smoother edges and minimizing post-processing.

3. Universal Compatibility with SL60/SL100 Systems

Engineered for seamless integration, the Plasma Shield Cap 9-8245 offers:

-

Plug-and-Play Installation: Matches OEM threading and dimensions for quick swaps without retrofitting.

-

Adaptive Power Handling: Operates efficiently across the full amperage range (SL60: 20–60A; SL100: 60–100A).

-

Mixed Fleet Optimization: Simplifies inventory management for facilities using multiple plasma systems.

4. Cost Efficiency Through Operational Savings

O 9-8245 Plasma Shield Cap drives long-term savings by:

-

Reducing Consumable Costs: Protects nozzles and electrodes, cutting replacement expenses by 25–30%.

-

Lowering Energy Use: Optimized plasma flow reduces gas consumption by 15–20%.

-

Minimizing Downtime: Robust design ensures fewer interruptions for maintenance.

5. Enhanced Safety and Heat Management

Safety is prioritized through innovative engineering:

-

Advanced Heat Dissipation: Integrated cooling channels prevent overheating, extending equipment lifespan.

-

Reduced Workplace Hazards: Deflects sparks and spatter away from operators, complying with OSHA safety standards.

-

Non-Conductive Materials: Ceramic construction eliminates electrical arcing risks.

Key Applications

-

Heavy Fabrication: Protects systems during high-volume cutting of structural steel, alloy plates, and machinery components.

-

Fabricação automotiva: Ensures precision trimming of exhaust systems, chassis, and coated body panels.

-

Aerospace Engineering: Maintains accuracy for turbine blades, brackets, and aircraft fittings.

-

Construção naval: Withstands abrasive environments during pipeline and marine-grade steel processing.

-

Artistic Metalwork: Enables intricate designs on copper, brass, or thin-gauge metals without distortion.

Conclusion: Elevate Efficiency and Reliability

O Plasma Shield Cap 9-8245 is a transformative upgrade for SL60/SL100 systems, merging rugged durability, precision engineering, and universal compatibility. By safeguarding components, reducing downtime, and enhancing cut quality, this shield cap ensures long-term cost savings and operational excellence across industries.

Invest in the Plasma Shield Cap 9-8245 to optimize performance, safety, and ROI—where advanced engineering meets industrial resilience.

| NAME | MODEL | SERIES | NAME | MODEL | SERIES |

| Eletrodo | 9-8215 | SL60/SL100 | Bocal | 9-8254 | SL60/SL100 |

| Eletrodo | 9-8232 | SL60/SL100 | Bocal | 9-8233 | SL60/SL100 |

| Bocal | 9-8205 | SL60/SL100 | Copo de escudo | 9-8218 | SL60/SL100 |

| Bocal | 9-8206 | SL60/SL100 | Copo de escudo | 9-8237 | SL60/SL100 |

| Bocal | 9-8207 | SL60/SL100 | Start Cartridge | 9-8277 | SL60/SL100 |

| Bocal | 9-8208 | SL60/SL100 | Start Cartridge | 9-8213 | SL60/SL100 |

| Bocal | 9-8209 | SL60/SL100 | Drag Shield Cap | 9-8235 | SL60/SL100 |

| Bocal | 9-8210 | SL60/SL100 | Cap | 9-8245 | SL60/SL100 |

| Bocal | 9-8211 | SL60/SL100 | Cap | 9-8238 | SL60/SL100 |

| Bocal | 9-8212 | SL60/SL100 | Cap | 9-8239 | SL60/SL100 |

| Bocal | 9-8233 | SL60/SL100 | Cap | 9-8256 | SL60/SL100 |

| Bocal | 9-8253 | SL60/SL100 | Cap | 9-8236 | SL60/SL100 |

| Bocal | 9-8231 | SL60/SL100 | Shield Cap/ Deflector |

9-8243 | SL60/SL100 |

| Bocal | 9-8225 | SL60/SL100 | Cap | 9-8258 | SL60/SL100 |

| Bocal | 9-8226 | SL60/SL100 | torch body | 9-8219 | SL60/SL101 |

| Bocal | 9-8227 | SL60/SL100 | torch body | 9-8220 | SL60/SL102 |

| Bocal | 9-8228 | SL60/SL100 | Stoff | 9-8281 | SL60/SL102 |

Compatibility, materials and application analysis of SL60 SL100 Plasma Shield Cap 9-8245

O Plasma Shield Cap 9-8245 is a precision-engineered component designed for SL60 and SL100 plasma cutting systems, offering robust protection, extended durability, and seamless integration. Below, we analyze its compatibility, material composition, and practical applications to demonstrate its value in industrial environments.

Compatibility: Universal Integration with SL60/SL100 Systems

O Plasma Shield Cap 9-8245 ensures flawless compatibility with both SL60 and SL100 plasma systems:

-

OEM-Specific Design: Matches original equipment specifications for threading, dimensions, and alignment, enabling plug-and-play installation without modifications.

-

Adaptive Power Range: Functions reliably across the full amperage spectrum (SL60: 20–60A; SL100: 60–100A), ensuring stability in low- and high-power operations.

-

Mixed Fleet Support: Simplifies inventory management for facilities using multiple SL60/SL100 units, reducing downtime and part mismatch errors.

This universal compatibility makes the shield cap ideal for workshops, factories, and mobile operations requiring rapid adaptability.

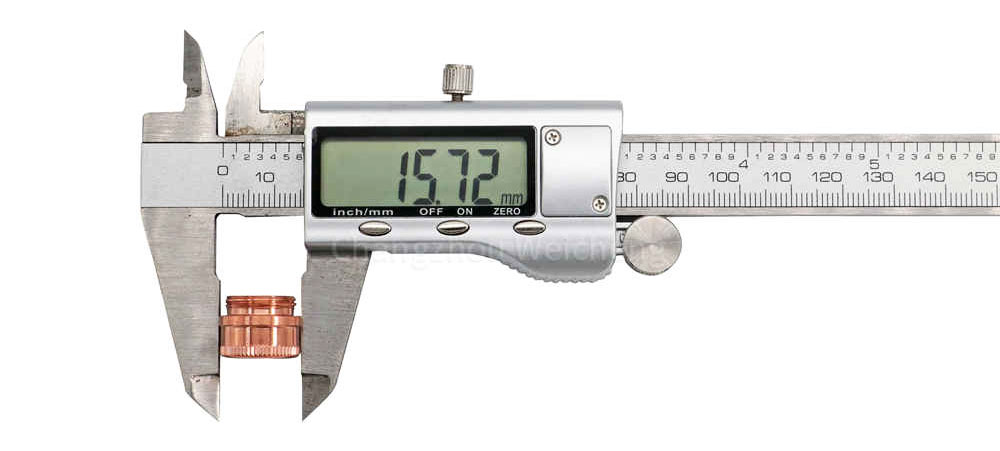

Material Composition: Engineered for Extreme Durability

O 9-8245 Plasma Shield Cap leverages advanced materials to withstand harsh operational conditions:

-

High-Temperature Ceramic Composite: Resists thermal degradation at temperatures exceeding 3,500°F (1,927°C), preventing warping or cracking during prolonged use.

-

Ablation-Resistant Coating: Protects against abrasive spatter from materials like galvanized steel, cast iron, and coated metals, reducing wear by 40% compared to standard caps.

-

Thermal Barrier Layer: Minimizes heat transfer to adjacent components, extending the lifespan of nozzles and electrodes.

-

Oxidation-Resistant Finish: Withstands corrosion in humid, marine, or chemically aggressive environments.

These materials ensure longevity in demanding settings, reducing replacement costs by 30–35%.

Application Analysis: Versatility Across Industries

O Plasma Shield Cap 9-8245 excels in diverse industrial scenarios, delivering precision and reliability:

1. Heavy Industrial Fabrication

-

Thick Plate Cutting: Protects components during high-amperage cutting of stainless steel (up to 55mm) and aluminum (up to 45mm), ensuring clean edges with minimal dross.

-

High-Volume Production: Shields systems during rapid cutting cycles for automotive frames, machinery parts, and structural beams.

2. Construction and Infrastructure

-

Structural Steel Processing: Withstands abrasive environments when cutting girders, rebar, and sheet metal for bridges or buildings.

-

Pipeline and Shipbuilding: Ensures durability during high-intensity cutting of large-diameter pipes and marine-grade steel.

3. Automotive and Aerospace Manufacturing

-

Precision Components: Maintains arc stability for exhaust systems, chassis parts, and aircraft brackets requiring ±0.2mm tolerance.

-

Coated Metal Handling: Resists wear when processing painted or galvanized surfaces common in automotive repairs.

4. Artistic and Custom Metalwork

-

Intricate Designs: Safeguards systems during detailed plasma cutting of copper, brass, or decorative artwork.

-

Thin-Gauge Metals: Reduces heat distortion in delicate projects, preserving material integrity.

Technical Advantages Driving Operational ROI

-

Tempo de inatividade reduzido: Extended lifespan lowers replacement frequency by 25–30%, critical for 24/7 operations.

-

Energy Efficiency: Optimized gas flow reduces shielding gas consumption by 15–20%, cutting operational costs.

-

Safety Compliance: Non-conductive ceramic materials and heat dissipation features align with OSHA standards, minimizing workplace hazards.

Conclusion: Precision and Protection for Industrial Excellence

O Plasma Shield Cap 9-8245 is a strategic upgrade for SL60/SL100 users, combining universal compatibility, rugged material engineering, and critical component protection. Whether tackling heavy fabrication, infrastructure projects, or precision tasks, this shield cap enhances productivity, reduces costs, and ensures consistent performance.

Upgrade to the Plasma Shield Cap 9-8245 to optimize plasma system longevity and efficiency—where advanced engineering meets industrial resilience.

Revisões

Ainda não há críticas.