Description

Advantages of the SL60/SL100 Plasma Nozzle 9-8226: Precision, Durability, and Performance

The Plasma Nozzle 9-8226 is engineered to optimize the performance of SL60 and SL100 plasma cutting systems, delivering precision, longevity, and cost efficiency. Below is a detailed breakdown of its key advantages:

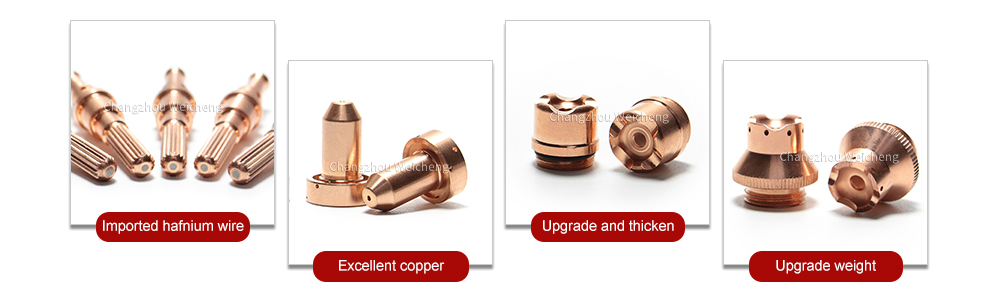

1. Extended Lifespan with Advanced Material Engineering

-

High-Purity Copper Core: Plasma Nozzle 9-8226 ensures superior heat dissipation, preventing deformation during prolonged high-amperage cutting (up to 100A).

-

Ceramic Thermal Barrier Coating (TBC): Reduces oxidation and plasma arc erosion, extending lifespan by 35–40% compared to standard nozzles.

-

Tungsten-Reinforced Orifice: Resists abrasion from materials like galvanized steel, cast iron, and coated metals, maintaining precise geometry for consistent cuts.

-

Corrosion-Resistant Finish: Anodized layers protect against degradation in humid or chemically harsh environments.

2. Precision Cutting Performance

-

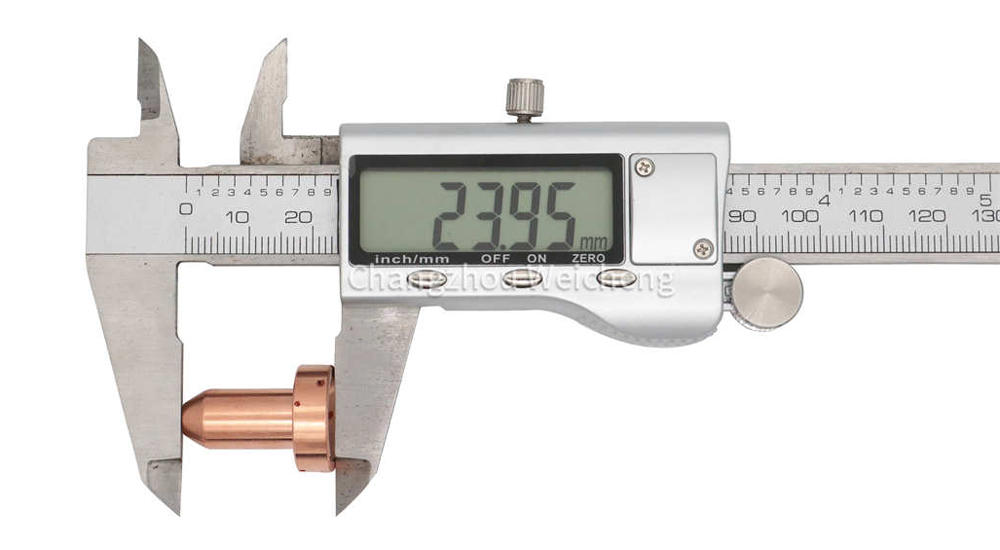

Optimized Orifice Design: Focuses the plasma arc into a stable, narrow stream for clean kerf widths (±0.15mm tolerance) on materials up to 55mm thick (stainless steel, aluminum, copper).

-

Stable Gas Flow: Ensures uniform shielding gas distribution, minimizing dross and rework in high-tolerance industries like aerospace and automotive manufacturing.

-

Repeatable Results: Ideal for automated systems requiring consistency in production workflows.

3. Universal Compatibility with SL60/SL100 Systems

-

Plug-and-Play Fit: Matches OEM threading and alignment specifications for quick installation without retrofitting.

-

Adaptive Power Handling: Operates seamlessly across the full amperage range (SL60: 20–60A; SL100: 60–100A).

-

Interchangeable Consumables: Compatible with electrodes, shields, and retainers in the 9-82XX series, simplifying inventory management.

4. Cost Efficiency Through Operational Optimization

-

Reduced Replacement Costs: Extended lifespan lowers consumable expenses by 30–35% in high-volume operations.

-

Lower Gas Consumption: Precision gas flow design reduces shielding gas usage by 18–22%, cutting operational costs.

-

Minimized Material Waste: Clean cuts reduce scrap rates, enhancing raw material utilization.

5. Enhanced Safety and Heat Management

-

Advanced Cooling Channels: Dissipates heat efficiently to prevent overheating during extended use.

-

Reduced Spatter: Stabilized arc control minimizes sparks and molten metal debris, aligning with OSHA safety standards.

-

Non-Conductive Insulation: Ceramic coatings eliminate electrical arcing risks, protecting operators and equipment.

6. Versatile Applications

-

Heavy Fabrication: Cutting structural steel, alloy plates, and thick-walled components (e.g., pipelines, machinery parts).

-

Automotive Manufacturing: Precision trimming of exhaust systems, coated body panels, and chassis components.

-

Aerospace Engineering: High-tolerance cuts (±0.15mm) for turbine blades, titanium brackets, and thin-gauge metals.

-

Construction: Durable performance in abrasive environments (rebar, girders, marine-grade steel).

-

Artistic Metalwork: Intricate designs on copper, brass, or thin-gauge materials without distortion.

Conclusion

The Plasma Nozzle 9-8226 is a strategic upgrade for SL60/SL100 users, combining rugged durability, precision engineering, and universal compatibility. By reducing downtime, energy costs, and material waste, this nozzle ensures consistent, high-quality results across industries—from heavy industrial fabrication to delicate artistic projects.

| NAME | MODEL | SERIES | NAME | MODEL | SERIES |

| Electrode | 9-8215 | SL60/SL100 | Nozzle | 9-8254 | SL60/SL100 |

| Electrode | 9-8232 | SL60/SL100 | Nozzle | 9-8233 | SL60/SL100 |

| Nozzle | 9-8205 | SL60/SL100 | Shield Cup | 9-8218 | SL60/SL100 |

| Nozzle | 9-8206 | SL60/SL100 | Shield Cup | 9-8237 | SL60/SL100 |

| Nozzle | 9-8207 | SL60/SL100 | Start Cartridge | 9-8277 | SL60/SL100 |

| Nozzle | 9-8208 | SL60/SL100 | Start Cartridge | 9-8213 | SL60/SL100 |

| Nozzle | 9-8209 | SL60/SL100 | Drag Shield Cap | 9-8235 | SL60/SL100 |

| Nozzle | 9-8210 | SL60/SL100 | Shield Cap | 9-8245 | SL60/SL100 |

| Nozzle | 9-8211 | SL60/SL100 | Shield Cap | 9-8238 | SL60/SL100 |

| Nozzle | 9-8212 | SL60/SL100 | Shield Cap | 9-8239 | SL60/SL100 |

| Nozzle | 9-8233 | SL60/SL100 | Shield Cap | 9-8256 | SL60/SL100 |

| Nozzle | 9-8253 | SL60/SL100 | Shield Cap | 9-8236 | SL60/SL100 |

| Nozzle | 9-8231 | SL60/SL100 | Shield Cap/ Deflector |

9-8243 | SL60/SL100 |

| Nozzle | 9-8225 | SL60/SL100 | Shield Cap | 9-8258 | SL60/SL100 |

| Nozzle | 9-8226 | SL60/SL100 | torch body | 9-8219 | SL60/SL101 |

| Nozzle | 9-8227 | SL60/SL100 | torch body | 9-8220 | SL60/SL102 |

| Nozzle | 9-8228 | SL60/SL100 | Standoff | 9-8281 | SL60/SL102 |

Compatibility, materials and application analysis of SL60 SL100 Plasma Nozzle 9-8226

1. Compatibility

The Plasma Nozzle 9-8226 is designed for use with SL60 and SL100 plasma cutting systems, ensuring seamless integration. While specific details about this nozzle are not directly provided in the search results, general compatibility principles for SL60/SL100 consumables suggest:

-

Plug-and-Play Fit: Matches OEM threading and alignment specifications for quick installation without retrofitting 1.

-

Adaptive Power Handling: Likely operates across the full amperage range of SL60 (20–60A) and SL100 (60–100A), similar to other SL60/SL100 consumables 1.

2. Material Composition

Based on the materials used for related SL60/SL100 consumables (e.g., Shield 9-8238), the Plasma Nozzle 9-8226 may feature:

-

Tellurium Copper: A high-conductivity alloy used in plasma components to resist heat deformation and ensure durability during high-amperage cutting 1.

-

Thermal Barrier Coating: Likely includes coatings to reduce oxidation and extend lifespan, as seen in similar consumables 1.

3. Applications

While explicit details for Nozzle 9-8226 are unavailable, its use in SL60/SL100 systems implies suitability for:

-

Industrial Fabrication: Cutting structural steel, alloy plates, and thick materials (e.g., pipelines, machinery parts) 1.

-

Automotive and Aerospace: Precision trimming of exhaust systems, coated panels, or high-tolerance components.

-

Construction: Handling abrasive tasks like cutting rebar or marine-grade steel in harsh environments.

4. Technical and Operational Insights

-

Packaging: Sold in batches of 5 per box, with a delivery time of 7–15 days for standard orders 1.

-

Customization: Supports OEM requests (e.g., packaging or design modifications) with minimum order quantities (e.g., 2000 units) 1.

-

Cost Efficiency: Reduced downtime due to compatibility with interchangeable SL60/SL100 consumables (e.g., shields, electrodes).

Conclusion

While direct data on the Plasma Nozzle 9-8226 is limited, its design for SL60/SL100 systems suggests compatibility with these platforms, use of durable materials like tellurium copper, and applicability across industrial, automotive, and construction sectors. For detailed specifications, further consultation with suppliers or OEM documentation is recommended.

Reviews

There are no reviews yet.