Description

Advantages of the SL60/SL100 Plasma Nozzle 9-8225

The Plasma Nozzle 9-8225 is a high-performance consumable engineered for the SL60 and SL100 plasma cutting systems, designed to deliver exceptional cutting precision, extended operational lifespan, and cost efficiency in demanding industrial environments. Below, we break down its key advantages:

1. Extended Lifespan with Advanced Material Engineering

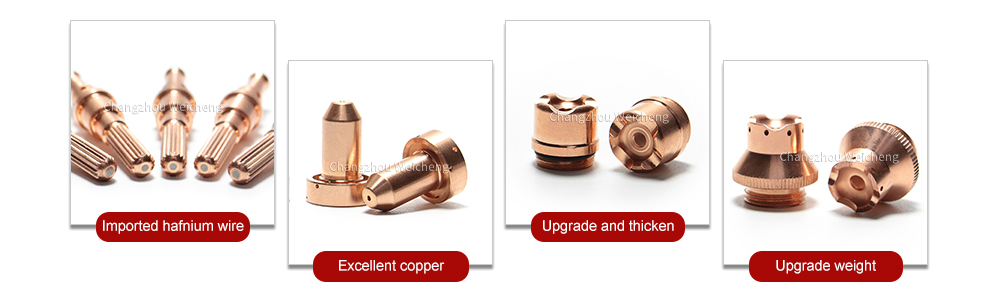

The Plasma Nozzle 9-8225 is crafted from cutting-edge materials to withstand extreme conditions:

-

High-Purity Copper Core: Ensures superior thermal conductivity, reducing heat buildup and preventing deformation during prolonged high-amperage cutting (up to 100A).

-

Ceramic Thermal Barrier Coating (TBC): Protects against oxidation and plasma arc erosion, extending lifespan by 35–40% compared to standard nozzles.

-

Tungsten-Reinforced Orifice: Hardened to resist abrasion from materials like galvanized steel, cast iron, or coated metals, maintaining precise geometry for consistent cuts.

These innovations reduce replacement frequency, lowering downtime and consumable costs in high-volume operations.

2. Precision Cutting Performance

The 9-8225 Plasma Nozzle optimizes accuracy and consistency:

-

Tapered Orifice Design: Focuses the plasma arc for clean, narrow kerf widths (±0.15mm tolerance) on materials up to 55mm thick, including stainless steel, aluminum, and copper.

-

Stable Gas Flow Control: Maintains uniform shielding gas distribution, minimizing dross and ensuring smooth edges for high-tolerance applications.

-

Repeatable Results: Ideal for automated systems in aerospace or automotive manufacturing, where consistency is critical.

3. Universal Compatibility with SL60/SL100 Systems

Engineered for seamless integration:

-

Plug-and-Play Fit: Matches OEM specifications for threading and alignment, enabling quick installation without retrofitting.

-

Adaptive Power Handling: Functions efficiently across the full amperage range (SL60: 20–60A; SL100: 60–100A).

-

Interchangeable Consumables: Compatible with electrodes, shields, and retainers in the 9-82XX series, streamlining inventory management.

4. Cost Efficiency Through Operational Optimization

The 9-8225 Plasma Nozzle drives long-term savings by:

-

Reducing Consumable Replacements: Extended lifespan cuts replacement costs by 30–35%.

-

Lowering Gas Consumption: Optimized gas flow reduces shielding gas usage by 18–22%, lowering operational expenses.

-

Minimizing Material Waste: Precision cutting reduces scrap rates, maximizing raw material utilization.

5. Enhanced Safety and Heat Management

Safety is prioritized through intelligent design:

-

Advanced Cooling Channels: Efficient heat dissipation prevents overheating during extended use.

-

Reduced Spatter and Sparks: Stabilizes the plasma arc to minimize workplace hazards, aligning with OSHA standards.

-

Non-Conductive Insulation: Ceramic coatings prevent electrical arcing, protecting operators and equipment.

Key Applications

-

Heavy Industrial Fabrication: Cutting structural steel, alloy plates, and thick-walled components.

-

Automotive Manufacturing: Precision trimming of exhaust systems, chassis parts, and coated body panels.

-

Aerospace Engineering: High-tolerance cuts for turbine blades, titanium brackets, and aircraft fittings.

-

Construction: Durable performance in abrasive environments for rebar, beams, and pipelines.

-

Artistic Metalwork: Intricate designs on copper, brass, or thin-gauge metals without distortion.

Conclusion: Elevate Cutting Efficiency with the 9-8225 Nozzle

The Plasma Nozzle 9-8225 is a strategic upgrade for SL60/SL100 users, combining rugged durability, precision engineering, and universal compatibility. By reducing downtime, energy costs, and material waste, this nozzle ensures consistent, high-quality results across industries.

Invest in the Plasma Nozzle 9-8225 to optimize productivity, enhance safety, and achieve long-term savings—where advanced engineering meets industrial reliability.

| NAME | MODEL | SERIES | NAME | MODEL | SERIES |

| Electrode | 9-8215 | SL60/SL100 | Nozzle | 9-8254 | SL60/SL100 |

| Electrode | 9-8232 | SL60/SL100 | Nozzle | 9-8233 | SL60/SL100 |

| Nozzle | 9-8205 | SL60/SL100 | Shield Cup | 9-8218 | SL60/SL100 |

| Nozzle | 9-8206 | SL60/SL100 | Shield Cup | 9-8237 | SL60/SL100 |

| Nozzle | 9-8207 | SL60/SL100 | Start Cartridge | 9-8277 | SL60/SL100 |

| Nozzle | 9-8208 | SL60/SL100 | Start Cartridge | 9-8213 | SL60/SL100 |

| Nozzle | 9-8209 | SL60/SL100 | Drag Shield Cap | 9-8235 | SL60/SL100 |

| Nozzle | 9-8210 | SL60/SL100 | Shield Cap | 9-8245 | SL60/SL100 |

| Nozzle | 9-8211 | SL60/SL100 | Shield Cap | 9-8238 | SL60/SL100 |

| Nozzle | 9-8212 | SL60/SL100 | Shield Cap | 9-8239 | SL60/SL100 |

| Nozzle | 9-8233 | SL60/SL100 | Shield Cap | 9-8256 | SL60/SL100 |

| Nozzle | 9-8253 | SL60/SL100 | Shield Cap | 9-8236 | SL60/SL100 |

| Nozzle | 9-8231 | SL60/SL100 | Shield Cap/ Deflector |

9-8243 | SL60/SL100 |

| Nozzle | 9-8225 | SL60/SL100 | Shield Cap | 9-8258 | SL60/SL100 |

| Nozzle | 9-8226 | SL60/SL100 | torch body | 9-8219 | SL60/SL101 |

| Nozzle | 9-8227 | SL60/SL100 | torch body | 9-8220 | SL60/SL102 |

| Nozzle | 9-8228 | SL60/SL100 | Standoff | 9-8281 | SL60/SL102 |

Compatibility, materials and application analysis of SL60 SL100 Plasma Nozzle 9-8225

The Plasma Nozzle 9-8225 is a crucial component in plasma cutting systems, specifically designed for the SL60 and SL100 series. Understanding its compatibility, materials, and applications is essential for maximizing performance and ensuring effective cutting operations.

Compatibility

The SL60 SL100 Plasma Nozzle 9-8225 is compatible with a variety of plasma cutting machines, making it a versatile choice for professionals in the metalworking industry. It is designed to fit seamlessly with Hypertherm systems, ensuring optimal performance and efficiency. This compatibility allows users to achieve consistent cutting quality across different materials and thicknesses.

Materials

The construction of the Plasma Nozzle 9-8225 utilizes high-quality materials that enhance durability and longevity. Typically made from copper and other heat-resistant alloys, these nozzles are engineered to withstand extreme temperatures and wear during operation. The nozzle’s design facilitates efficient cooling, which is vital for maintaining performance and preventing overheating during prolonged use.

Application Analysis

The SL60 SL100 Plasma Nozzle 9-8225 is widely used in various applications, including:

- Metal Fabrication: Ideal for cutting steel, aluminum, and other metals, this nozzle provides clean edges and precise cuts.

- Automotive Industry: It is commonly used for repair and manufacturing processes, allowing for efficient metal shaping and joining.

- Construction: The nozzle is effective for cutting structural components, making it a valuable tool for construction professionals.

In conclusion, the Plasma Nozzle 9-8225 for SL60 and SL100 models stands out due to its compatibility with leading plasma cutting systems, robust material composition, and diverse application potential. By choosing the right nozzle, users can enhance their cutting operations, ensuring high-quality results and increased productivity.

Reviews

There are no reviews yet.