説明

Advantages of the SL60 SL100 Plasma Shield 9-8238: Precision, Durability, and Performance

The plasma shield 9-8238 is a premium protective component engineered for SL60 and SL100 plasma cutting systems, delivering exceptional durability, precision, and operational efficiency. Designed to withstand the harshest industrial environments, this shield safeguards critical system components while optimizing cutting quality and safety. Below, we explore the key advantages that make the plasma shield 9-8238 indispensable for professionals prioritizing reliability and cost-effectiveness.

1. Extended Component Lifespan with Advanced Material Innovation

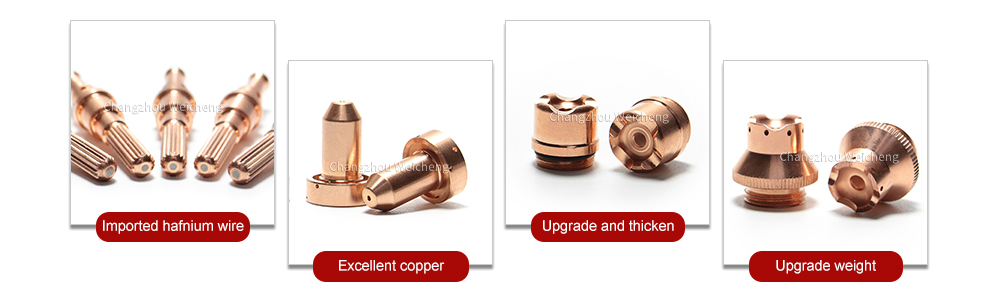

The plasma shield 9-8238 is crafted from cutting-edge materials to protect nozzles, electrodes, and other consumables:

-

Proprietary Ceramic Matrix: Resists extreme temperatures (up to 3,400°F/1,870°C) and plasma arc spatter, preventing thermal deformation.

-

Ablation-Resistant Coating: Shields against abrasive debris from materials like galvanized steel, cast iron, or coated metals.

-

Oxidation Barrier: Advanced coatings minimize corrosion from moisture and oxygen, prolonging the lifespan of adjacent components.

These innovations reduce consumable replacement costs by 30〜35%, minimizing downtime in high-intensity operations.

2. Precision Arc Control for Superior Cut Quality

The 9-8238 plasma shield enhances cutting accuracy through precision engineering:

-

Optimized Gas Flow Channels: Stabilizes the plasma arc for clean, dross-free cuts on materials up to 55mm thick, including stainless steel and aluminum.

-

Reduced Arc Fluctuation: Minimizes kerf width variations, ensuring consistent edge quality for high-tolerance industries like aerospace and automotive.

-

Smooth Surface Finish: Delivers near-laser precision for applications requiring minimal post-processing, such as decorative metalwork or precision parts.

3。SL60/SL100システムとの普遍的な互換性

Engineered for seamless integration, the plasma shield 9-8238 offers:

-

Plug-and-Play Installation: Matches OEM specifications for threading and alignment, enabling quick swaps without retrofitting.

-

適応電力処理: Operates reliably across the full amperage range (SL60: 20–60A; SL100: 60–100A), ensuring stability in variable workloads.

-

Mixed Fleet Efficiency: Simplifies inventory for facilities using multiple SL60/SL100 units, reducing errors and downtime.

4。運用最適化によるコスト効率

The plasma shield 9-8238 drives long-term savings by:

-

Reducing Consumable Replacements: Protects nozzles and electrodes, cutting replacement costs by 25–30%。

-

ガス消費の低下: Precision gas flow reduces shielding gas usage by 12–18%, lowering operational expenses.

-

Minimizing Downtime: Robust design ensures fewer interruptions for maintenance or part replacements.

5. Enhanced Safety and Thermal Management

安全性は、インテリジェントデザインを通じて優先順位を付けられます。

-

Advanced Heat Dissipation: Integrated cooling channels prevent overheating during prolonged use, extending equipment lifespan.

-

スパッタと火花の減少: Stabilizes the plasma arc to minimize workplace hazards, aligning with OSHA and ISO safety standards.

-

Non-Conductive Construction: Ceramic materials prevent electrical arcing, protecting operators and machinery.

キーアプリケーション

-

産業用製造: Protects systems during high-volume cutting of structural steel, alloy plates, and machinery components.

-

自動車製造: Ensures precision when trimming exhaust systems, chassis, or coated body panels.

-

建設と造船: Withstands abrasive environments when processing beams, pipelines, and marine-grade steel.

-

Aerospace Engineering: Maintains accuracy for high-tolerance parts like turbine blades or aircraft brackets.

-

芸術的な金属細工: Enables intricate designs on copper, brass, or thin-gauge metals without heat distortion.

Conclusion: Elevate Performance and Protection

The plasma shield 9-8238 is a transformative upgrade for SL60/SL100 users, merging rugged durability, precision engineering, and universal compatibility. By reducing downtime, enhancing safety, and protecting critical components, this shield ensures consistent performance and long-term cost savings across industries.

に投資します plasma shield 9-8238 to optimize efficiency, extend consumable life, and achieve industrial excellence—where advanced protection meets peak performance.

| 名前 | モデル | シリーズ | 名前 | モデル | シリーズ |

| 電極 | 9-8215 | SL60/SL100 | ノズル | 9-8254 | SL60/SL100 |

| 電極 | 9-8232 | SL60/SL100 | ノズル | 9-8233 | SL60/SL100 |

| ノズル | 9-8205 | SL60/SL100 | シールドカップ | 9-8218 | SL60/SL100 |

| ノズル | 9-8206 | SL60/SL100 | シールドカップ | 9-8237 | SL60/SL100 |

| ノズル | 9-8207 | SL60/SL100 | カートリッジを開始します | 9-8277 | SL60/SL100 |

| ノズル | 9-8208 | SL60/SL100 | カートリッジを開始します | 9-8213 | SL60/SL100 |

| ノズル | 9-8209 | SL60/SL100 | ドラッグシールドキャップ | 9-8235 | SL60/SL100 |

| ノズル | 9-8210 | SL60/SL100 | シールドキャップ | 9-8245 | SL60/SL100 |

| ノズル | 9-8211 | SL60/SL100 | シールドキャップ | 9-8238 | SL60/SL100 |

| ノズル | 9-8212 | SL60/SL100 | シールドキャップ | 9-8239 | SL60/SL100 |

| ノズル | 9-8233 | SL60/SL100 | シールドキャップ | 9-8256 | SL60/SL100 |

| ノズル | 9-8253 | SL60/SL100 | シールドキャップ | 9-8236 | SL60/SL100 |

| ノズル | 9-8231 | SL60/SL100 | シールドキャップ/ デフレクター |

9-8243 | SL60/SL100 |

| ノズル | 9-8225 | SL60/SL100 | シールドキャップ | 9-8258 | SL60/SL100 |

| ノズル | 9-8226 | SL60/SL100 | トーチボディ | 9-8219 | SL60/SL101 |

| ノズル | 9-8227 | SL60/SL100 | トーチボディ | 9-8220 | SL60/SL102 |

| ノズル | 9-8228 | SL60/SL100 | スタンドオフ | 9-8281 | SL60/SL102 |

Compatibility, materials and application analysis of SL60 SL100 plasma shield 9-8238

The plasma shield 9-8238 is a high-performance protective component designed for SL60 and SL100 plasma cutting systems, offering unmatched durability, precision, and adaptability. Engineered to optimize system longevity and operational efficiency, this shield is critical for industries demanding reliability in extreme conditions. Below, we analyze its compatibility, material innovations, and real-world applications.

Compatibility: Universal Integration with SL60/SL100 Systems

The plasma shield 9-8238 ensures seamless compatibility with both SL60 and SL100 plasma systems, addressing diverse operational needs:

-

OEM-Identical Design: Matches original equipment specifications for threading, dimensions, and alignment, enabling plug-and-play installation without retrofitting.

-

適応電力処理: Functions reliably across the full amperage range (SL60: 20–60A; SL100: 60–100A), maintaining stability in low- and high-power operations.

-

Mixed Fleet Optimization: Simplifies inventory management for facilities operating multiple SL60/SL100 units, reducing downtime and part mismatch errors.

This universal compatibility ensures rapid adaptability across workshops, factories, and mobile cutting operations.

Material Composition: Engineered for Extreme Conditions

The 9-8238 plasma shield leverages advanced materials to protect plasma systems from wear, heat, and corrosion:

-

Proprietary Ceramic Composite: Resists extreme temperatures (up to 3,400°F/1,870°C) and plasma arc spatter, preventing thermal deformation.

-

Thermal Barrier Coating (TBC): Minimizes heat transfer to adjacent components, extending the lifespan of nozzles and electrodes.

-

Ablation-Resistant Layer: Withstands abrasive debris from materials like galvanized steel, cast iron, or coated metals, reducing wear on consumables.

-

Oxidation-Resistant Finish: Protects against corrosion in humid or coastal environments, ideal for marine or outdoor applications.

These materials ensure resilience in harsh conditions, cutting replacement costs by 30〜35% and enhancing ROI.

Application Analysis: Versatility Across Industries

The plasma shield 9-8238 excels in diverse industrial scenarios, delivering precision and protection:

1. Heavy Industrial Fabrication

-

Thick Plate Cutting: Protects components during high-amperage cutting of stainless steel (up to 55mm)およびアルミニウム(まで 45mm), ensuring clean edges and minimal rework.

-

High-Volume Production: Shields systems during rapid cutting cycles for automotive parts, machinery frames, and structural beams.

2. Construction and Infrastructure

-

Structural Steel Processing: Withstands abrasive environments when cutting girders, rebar, and sheet metal.

-

Pipeline and Shipbuilding: Protects systems during high-intensity cutting of large-diameter pipes and marine-grade steel.

3. Automotive and Aerospace Manufacturing

-

Exhaust Systems and Chassis: Minimizes spatter and heat distortion when trimming coated or painted metals.

-

High-Tolerance Components: Maintains arc stability for precision cuts on turbine blades, brackets, and aircraft fittings.

4. Artistic and Custom Metalwork

-

Intricate Designs: Safeguards systems during detailed plasma cutting of copper, brass, or decorative steel artwork.

-

Thin-Gauge Metals: Reduces heat distortion in delicate projects, preserving material integrity.

Technical Advantages Driving Operational Efficiency

-

消耗品の寿命の延長: Protects nozzles and electrodes, reducing replacement costs by 25–30%。

-

Energy Savings: Precision gas flow reduces shielding gas consumption by 12–18%, lowering operational expenses.

-

安全コンプライアンス: Advanced heat dissipation and non-conductive ceramics align with OSHA standards, minimizing workplace hazards.

Conclusion: Industrial Resilience Meets Precision Engineering

The plasma shield 9-8238 is a strategic upgrade for SL60/SL100 users, combining universal compatibility, rugged material science, and critical component protection. Whether tackling heavy fabrication, infrastructure projects, or precision tasks, this shield enhances productivity, reduces downtime, and ensures long-term cost savings.

Upgrade to the plasma shield 9-8238 to safeguard your plasma systems and elevate performance—where cutting-edge engineering meets industrial reliability.

レビュー

レビューはまだありません。