説明

Advantages of the SL60/SL100 Plasma Nozzle 9-8225

The Plasma Nozzle 9-8225 is a high-performance consumable engineered for the SL60 and SL100 plasma cutting systems, designed to deliver exceptional cutting precision, extended operational lifespan, and cost efficiency in demanding industrial environments. Below, we break down its key advantages:

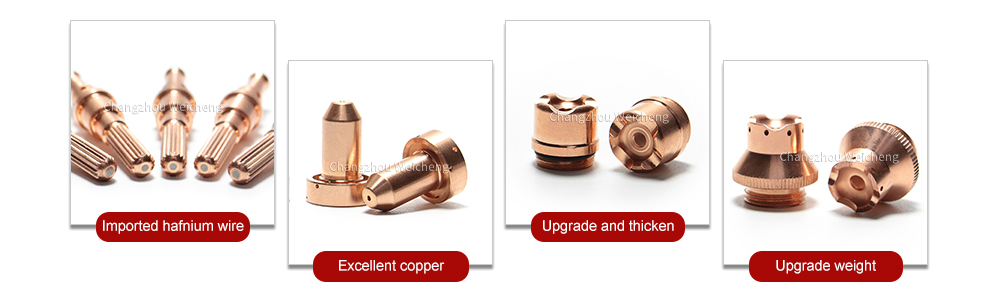

1。高度な材料工学で寿命を延ばしました

The Plasma Nozzle 9-8225 極端な条件に耐えるために最先端の素材から作られています。

-

高純度の銅コア: Ensures superior thermal conductivity, reducing heat buildup and preventing deformation during prolonged high-amperage cutting (up to 100A)。

-

セラミックサーマルバリアコーティング(TBC): Protects against oxidation and plasma arc erosion, extending lifespan by 35–40% 標準ノズルと比較して。

-

タングステン強化オリフィス: Hardened to resist abrasion from materials like galvanized steel, cast iron, or coated metals, maintaining precise geometry for consistent cuts.

These innovations reduce replacement frequency, lowering downtime and consumable costs in high-volume operations.

2。精密切断性能

The 9-8225 Plasma Nozzle optimizes accuracy and consistency:

-

Tapered Orifice Design: Focuses the plasma arc for clean, narrow kerf widths (±0.15mm tolerance) on materials up to 55mm thick、ステンレス鋼、アルミニウム、銅など。

-

Stable Gas Flow Control: Maintains uniform shielding gas distribution, minimizing dross and ensuring smooth edges for high-tolerance applications.

-

Repeatable Results: Ideal for automated systems in aerospace or automotive manufacturing, where consistency is critical.

3。SL60/SL100システムとの普遍的な互換性

シームレスな統合のために設計されています:

-

プラグアンドプレイのフィット: Matches OEM specifications for threading and alignment, enabling quick installation without retrofitting.

-

適応電力処理:フルアンペア範囲全体で効率的に機能します(SL60:20–60A; SL100:60–100A)。

-

Interchangeable Consumables: Compatible with electrodes, shields, and retainers in the 9-82XX series, streamlining inventory management.

4。運用最適化によるコスト効率

The 9-8225 Plasma Nozzle drives long-term savings by:

-

Reducing Consumable Replacements: Extended lifespan cuts replacement costs by 30〜35%。

-

ガス消費の低下: Optimized gas flow reduces shielding gas usage by 18–22%, lowering operational expenses.

-

材料の無駄を最小限に抑えます:精密な削減により、スクラップレートが減少し、原材料の利用が最大化されます。

5。安全性と熱管理の強化

安全性は、インテリジェントデザインを通じて優先順位を付けられます。

-

Advanced Cooling Channels:効率的な熱散逸は、長時間使用中の過熱を防ぎます。

-

スパッタと火花の減少: Stabilizes the plasma arc to minimize workplace hazards, aligning with OSHA standards.

-

非伝導断熱:セラミックコーティングは、電気的なアーク、オペレーターと機器の保護を防ぎます。

キーアプリケーション

-

重い工業用製造: Cutting structural steel, alloy plates, and thick-walled components.

-

自動車製造: Precision trimming of exhaust systems, chassis parts, and coated body panels.

-

Aerospace Engineering: High-tolerance cuts for turbine blades, titanium brackets, and aircraft fittings.

-

工事: Durable performance in abrasive environments for rebar, beams, and pipelines.

-

芸術的な金属細工: Intricate designs on copper, brass, or thin-gauge metals without distortion.

Conclusion: Elevate Cutting Efficiency with the 9-8225 Nozzle

The Plasma Nozzle 9-8225 SL60/SL100ユーザーの戦略的アップグレードであり、頑丈な耐久性、精密エンジニアリング、普遍的な互換性を組み合わせています。ダウンタイム、エネルギーコスト、材料廃棄物を削減することにより、このノズルは、業界全体で一貫した高品質の結果を保証します。

に投資します Plasma Nozzle 9-8225 to optimize productivity, enhance safety, and achieve long-term savings—where advanced engineering meets industrial reliability.

| 名前 | モデル | シリーズ | 名前 | モデル | シリーズ |

| 電極 | 9-8215 | SL60/SL100 | ノズル | 9-8254 | SL60/SL100 |

| 電極 | 9-8232 | SL60/SL100 | ノズル | 9-8233 | SL60/SL100 |

| ノズル | 9-8205 | SL60/SL100 | シールドカップ | 9-8218 | SL60/SL100 |

| ノズル | 9-8206 | SL60/SL100 | シールドカップ | 9-8237 | SL60/SL100 |

| ノズル | 9-8207 | SL60/SL100 | カートリッジを開始します | 9-8277 | SL60/SL100 |

| ノズル | 9-8208 | SL60/SL100 | カートリッジを開始します | 9-8213 | SL60/SL100 |

| ノズル | 9-8209 | SL60/SL100 | ドラッグシールドキャップ | 9-8235 | SL60/SL100 |

| ノズル | 9-8210 | SL60/SL100 | シールドキャップ | 9-8245 | SL60/SL100 |

| ノズル | 9-8211 | SL60/SL100 | シールドキャップ | 9-8238 | SL60/SL100 |

| ノズル | 9-8212 | SL60/SL100 | シールドキャップ | 9-8239 | SL60/SL100 |

| ノズル | 9-8233 | SL60/SL100 | シールドキャップ | 9-8256 | SL60/SL100 |

| ノズル | 9-8253 | SL60/SL100 | シールドキャップ | 9-8236 | SL60/SL100 |

| ノズル | 9-8231 | SL60/SL100 | シールドキャップ/ デフレクター |

9-8243 | SL60/SL100 |

| ノズル | 9-8225 | SL60/SL100 | シールドキャップ | 9-8258 | SL60/SL100 |

| ノズル | 9-8226 | SL60/SL100 | トーチボディ | 9-8219 | SL60/SL101 |

| ノズル | 9-8227 | SL60/SL100 | トーチボディ | 9-8220 | SL60/SL102 |

| ノズル | 9-8228 | SL60/SL100 | スタンドオフ | 9-8281 | SL60/SL102 |

Compatibility, materials and application analysis of SL60 SL100 Plasma Nozzle 9-8225

The Plasma Nozzle 9-8225 is a crucial component in plasma cutting systems, specifically designed for the SL60 and SL100 series. Understanding its compatibility, materials, and applications is essential for maximizing performance and ensuring effective cutting operations.

互換性

The SL60 SL100 Plasma Nozzle 9-8225 is compatible with a variety of plasma cutting machines, making it a versatile choice for professionals in the metalworking industry. It is designed to fit seamlessly with Hypertherm systems, ensuring optimal performance and efficiency. This compatibility allows users to achieve consistent cutting quality across different materials and thicknesses.

Materials

The construction of the Plasma Nozzle 9-8225 utilizes high-quality materials that enhance durability and longevity. Typically made from copper and other heat-resistant alloys, these nozzles are engineered to withstand extreme temperatures and wear during operation. The nozzle’s design facilitates efficient cooling, which is vital for maintaining performance and preventing overheating during prolonged use.

Application Analysis

The SL60 SL100 Plasma Nozzle 9-8225 is widely used in various applications, including:

- 金属加工: Ideal for cutting steel, aluminum, and other metals, this nozzle provides clean edges and precise cuts.

- 自動車産業: It is commonly used for repair and manufacturing processes, allowing for efficient metal shaping and joining.

- 工事: The nozzle is effective for cutting structural components, making it a valuable tool for construction professionals.

In conclusion, the Plasma Nozzle 9-8225 for SL60 and SL100 models stands out due to its compatibility with leading plasma cutting systems, robust material composition, and diverse application potential. By choosing the right nozzle, users can enhance their cutting operations, ensuring high-quality results and increased productivity.

レビュー

レビューはまだありません。